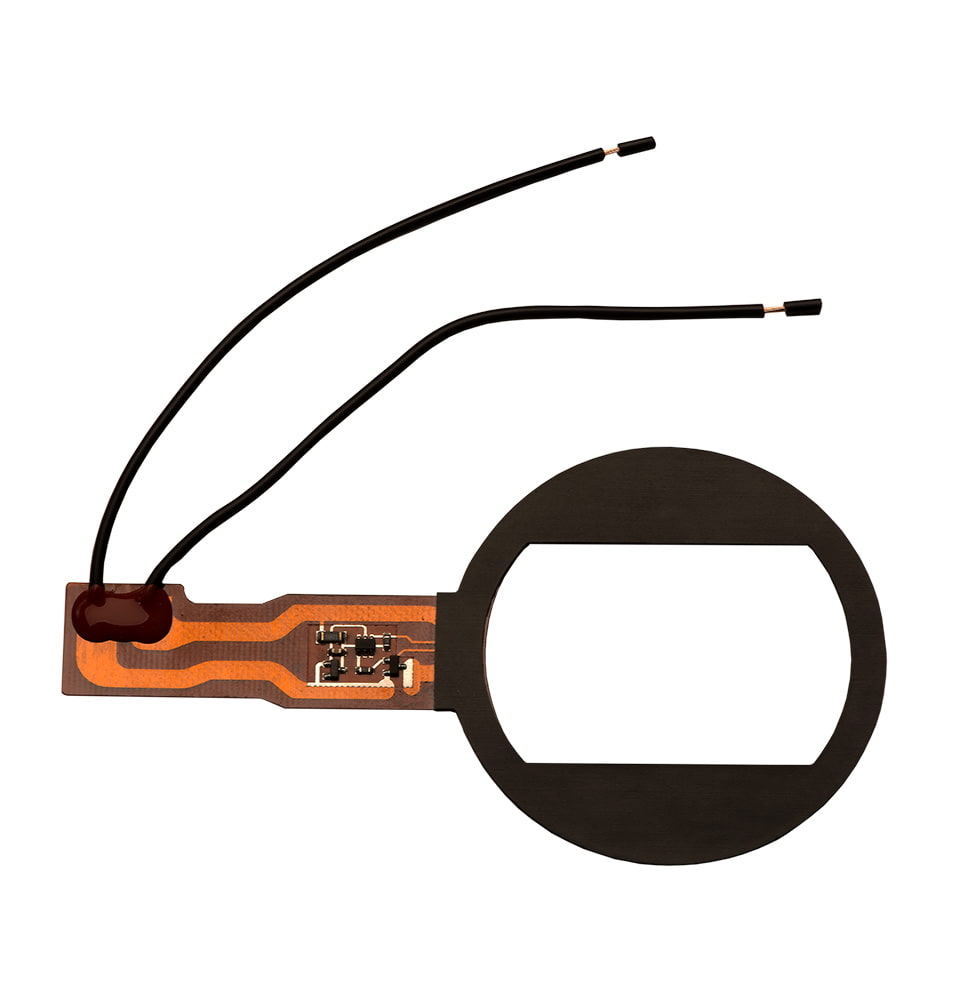

Smart heater concept with integrated solutions.

Maintaining correct temperature is critical for many applications and we provide complete solutions to ensure reliable temperature management. Our engineers will not only suggest solutions, they can also take part in and contribute to your product development by using our advanced technical tools and lab facilities. Our extensive experience and competence as well as our reliable quality and service are a guarantee of your success

The demand for smart and simple solutions creates new applications and we offer solutions with integrated thermal controllers and sensors. Etched foil heating elements are used with thermostats, resistance-controlled, PTC, PT100/PT1000, thermocouple and overheat protection.

Temperature management and energy balance.

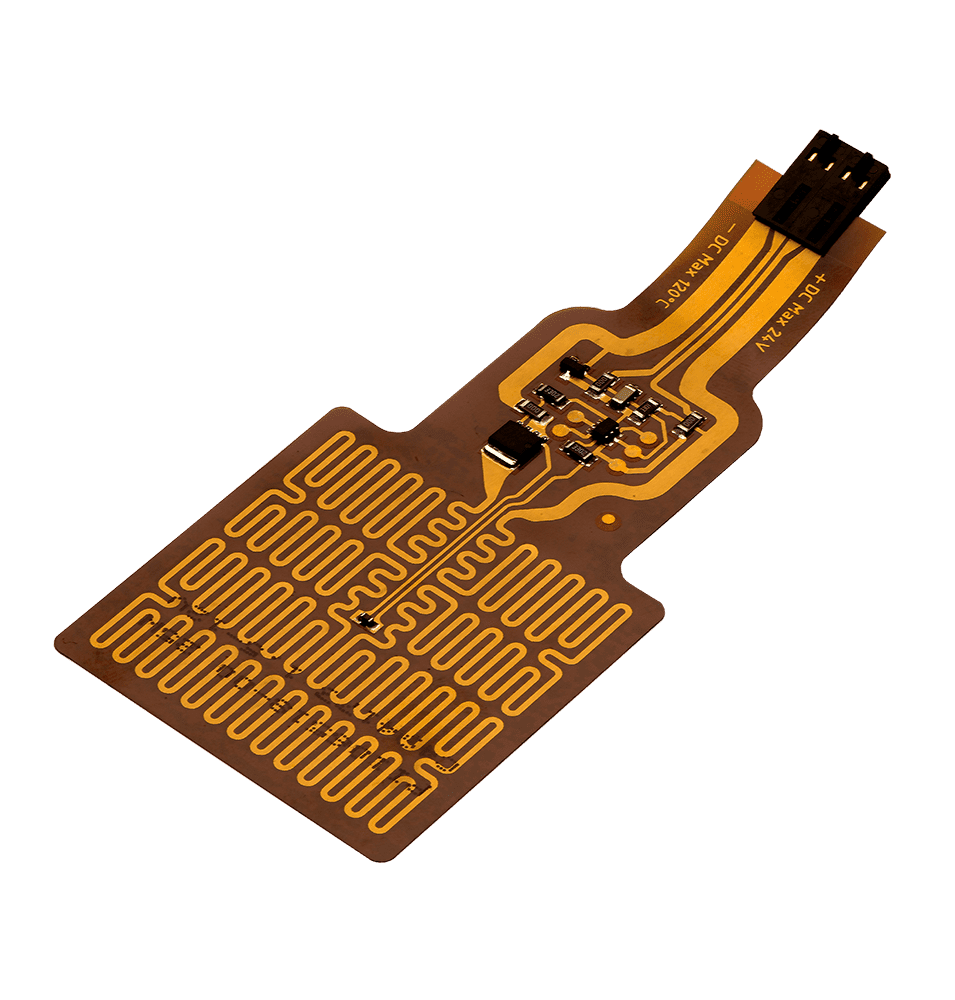

Etched foil heaters provide excellent thermal transfer where you need it most. Flexible heaters are used in thermal control design to protect components under cold-case environmental conditions or to make up for heat that is not dissipated. It is usually necessary to arrange some form of control to ensure that the desired temperature is maintained; accurate temperature control is therefore needed.

This can be achieved with bimetallic electromechanical thermostats when temperatures and surface ratings are low, while electronic thermostats are preferred when temperatures and surface loads are high.

We can fit thermostats, temperature fuses and sensors of thermo-element type, thermistors and resistance sensors directly to elements in accordance with customer specifications. This helps to ensure reliable control.

Design guidelines

Calculation of power

The following information will assist in the design of elements and rough calculation of data. Optimum power and temperature conditions for specific applications are usually determined experimentally. The following formula can be used to determine approximately the required rating P (power) to heat a given material.

Advantages for etched foil heaters

- Thin, flexible and lightweight

- Customized shapes

- Multiple temperature zones

- Simple assembly

- Quick heating

- Efficient heat transmission

- High quality

- Wide material selection

We provide DVP performance testing

- To validate the design, we perform tests needed to fulfill the specifications

- Temperature profile (sensor and image)

- Resistance to climate and environment

- Electrical durability and resistance

- Specific customer requirements